Since last speaking to Aerosonic, the company has progressed in its provision of complete air data systems to meet the demands of the biggest aerospace organizations. Alexandre Lebeau, Vice President of Sales and Marketing, and Greg Van Bemden, Vice President of Engineering, delve deeper.

AVIONICS PRECISION, ACCURACY, AND SUPPORT

The last 12 months have witnessed considerable turbulence in the aerospace sector, following significant global supply chain constraints arising from the aftermath of the COVID-19 pandemic, compounded by increased military demand from multiple global conflicts and recent issues found in Boeing aircraft fleets.

These challenges have highlighted the growing need for a robust supply chain of dependable parts manufacturers.

“Supply chain delays and issues with original equipment manufacturers (OEMs) have provided Aerosonic with an opportunity to gain additional market shares across the entire commercial transport segment, with our expanded Federal Aviation Administration (FAA) Parts Manufacturing Approval (PMA) product line for the Airbus and Boeing family of aircraft,” introduces Alexandre Lebeau, Vice President of Sales and Marketing.

Furthermore, the growing level of worldwide conflict has caused the increased use of unmanned aerial vehicles (UAVs), thus increasing the demand for lighter and flexible air data products that can be utilized on smaller and more constrained aircraft.

Ongoing conflicts around the world have also raised global defense spending, as aircraft manufacturers use proven technology to accelerate the entry of new aircraft into service and bring new capabilities, which is well suited for Aerosonic’s second-generation of integrated multi-function probes (IMPs).

EXPERTS IN AVIONICS

In the past year, Aerosonic has substantially increased its avionics capabilities, fortifying itself as a best-in-class provider for notable names in the industry.

For instance, the company recently received an FAA PMA for an updated pitot probe that met the latest AS5562 icing standards for all A320s, A330s, and A340s aircraft types. This probe is now available as a one-to-one replacement for any OEM products onboard these Airbus fleets.

Meanwhile, the company’s legacy pitot probe on the 737 family was also approved by the FAA to cover the 737 MAX family of aircraft, which is set to resolve recent OEM reliability issues.

“Additionally, the PMA of the pitot probe was expanded to cover the latest Boeing 737 MAX aircraft without modifications to the legacy design. This is thanks to its superior design and robust service history, thus complementing the overall Boeing PMA portfolio,” highlights Greg Van Bemden, Vice President of Engineering.

On top of this, the company recently completed the Preliminary Design Review (PDR) of the latest generation of multi-function probes. The resulting new product line, MULTISENSE™, consists of a family of probes and mating Air Data Computers (ADC) that are aimed at smaller aircraft, such as UAVs and electric vertical take-off and landing (eVTOL) aircraft, alongside a fully integrated version for regional and business aviation.

The customer benefits of MULTISENSE™ include optimized weight and size, fewer parts on the aircraft, higher reliability and availability, and lower integration and maintenance costs translating into the improved total cost of ownership for the operators.

“As aircraft continue to fly higher and faster, the requirements for more robust air data systems are steadily increasing. As a result, Aerosonic has developed an air data flight test boom capable of surviving the extreme environments found in modern military aircraft,” opens Greg Van Bemden, Vice President of Engineering.

The air data flight test boom measures total and static pressure, total air temperature, angle of attack (AoA), and angle of sideslip (AoS). It is then used during test flight campaigns to calibrate the aircraft’s integrated air data systems.

MULTI-FUNCTION FIXED AIR DATA PROBES

A highly significant ongoing project for Aerosonic is the expansion of its multi-function fixed air data probes for UAVs and eVTOLs. The company recently developed a modular architecture for the quick customization of probe bases to match unique aircraft mounting requirements.

The modular architecture extends to design assurance level A (DAL A) air data computers to reduce the amount of testing required for new multi-function fixed air data probe configurations.

The Technical Standard Orders (TSO)-certified MULTISENSE™ provides Aerosonic with the unique ability to offer any aircraft a multi-function solution, whether integrated or federated, with lower integration costs.

On top of this, the second generation of IMPs for military fighter jets and trainers have been flying for more than a year, with the products nearing the final approval stage for low-rate initial production (LRIP), ready for four new aircraft platforms being fielded across Europe and Asia.

FLYING HIGH ABOVE THE REST

The organization continues to differentiate itself through strategic partnerships that elevate its capabilities to meet growing demand.

“One of Aerosonic’s strengths is its ability to focus on the projects that yield the most return for our customers and shareholders,” states Lebeau.

For example, leveraging its extensive air data solutions portfolio, the company has partnered with another major air data system provider to enable the sale of complete air data systems to its evolving customer base.

“Safety regulations require dissimilar air data systems as primary and back-up systems. Few companies can offer both for every aircraft,” affirms Van Bemden.

The company is equally a step ahead of its competitors in supporting its customers’ aircraft-level critical point analysis (CPA).

Aerosonic recently made a significant capital investment to increase its computational capability, enabling it to place air data products in optimum positions on aircraft and determine the concentration factors needed to safely test products according to the latest standards.

Another differentiating factor is the further expansion of Aerosonic’s flight test boom product line, which now possesses a larger range of AoA and AoS capabilities. Its portfolio was also expanded to include a new line of booms for high-stress military environments as well as smaller booms to support aircraft production purposes.

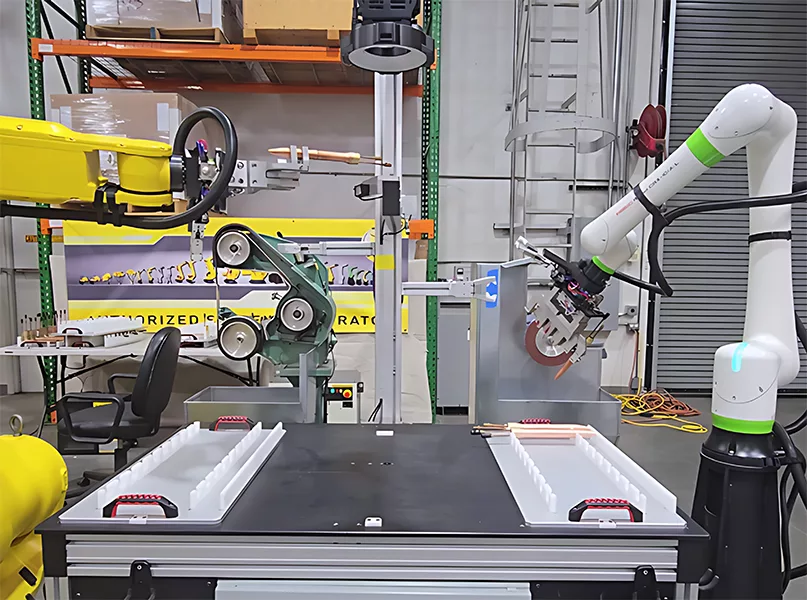

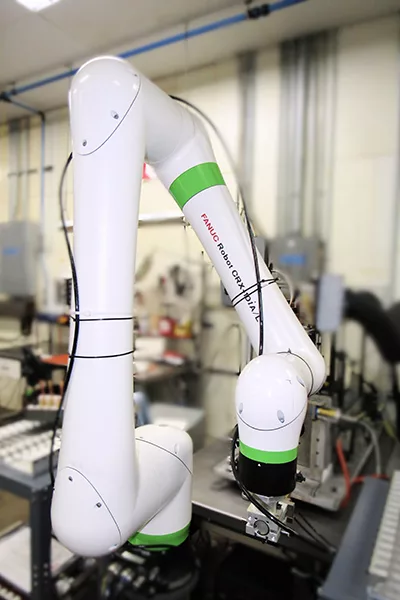

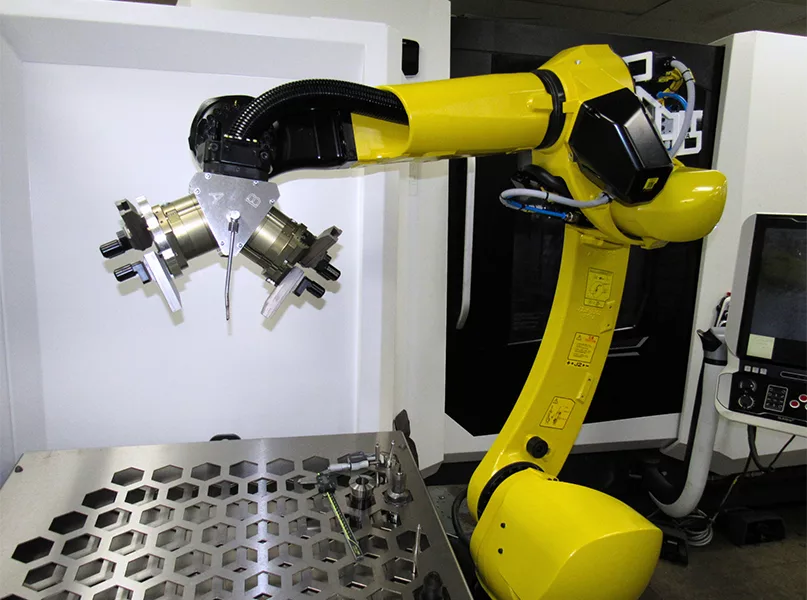

In addition, the company has significantly invested in automating critical steps in the probe manufacturing process, such as brazing and polishing. This will improve the overall quality and on-time delivery of its core products whilst preparing for the ramp-up of advanced air mobility.

“By investing in the automation of the brazing and polishing processes across our probe product lines, we expect to see significant improvements in the overall quality and delivery of our core products,” details Van Bemden.

To add to this, Aerosonic also consistently commits to high standards of health and safety.

“Lastly, we increased our contributions to multiple SAE Air Data Working Groups by hosting two of their quarterly meetings at our Clearwater facility in Florida. The groups are creating and improving standards to maintain the safety level that everyone expects from the aerospace industry,” voices Van Bemden.

ACHIEVING CONTINUOUS GROWTH

Looking towards the future, Aerosonic has a number of projects in the pipeline that it is eager to commence once resources are available. For instance, the company’s main focus includes designing products for efficient heating and aerodynamic performance.

“Our future project funnel leverages these core competencies to expand our traditional offerings and grow through adjacent product lines,” reveals Van Bemden.

Another priority for the company is innovating its manufacturing processes.

“We’ve demonstrated success in implementing new automation solutions for our legacy and next-generation processes, which allow Aerosonic to insource more subcomponents and increase our capabilities and capacity,” concludes Van Bemden.

This ultimately allows the company to better serve its customers with less volatility within the supply chain, providing shorter lead times.

With a stringent target to achieve continuous growth year on year, Aerosonic is also investing heavily in productivity improvements to steadily increase its quality and on-time delivery.

These elements facilitate the organization’s foundation of trust with customers, which allows the company to bring in new businesses from a focused portfolio of new projects.

In 2024, Aerosonic is looking forward to delivering the first shipsets of MULTISENSE™ to its launch customers in order to support their test flight campaigns and type certification efforts.

Finally, this year also sees the company transitioning its second generation of IMPs and integrated static ports (ISPs) into low-rate initial production, further pushing the boundaries for aerospace innovation.