Driven by the desire to pursue comprehensive functionality embodied in simplicity, MTM Pty Ltd’s automotive innovation prioritises ease of assembly. Mark Albert, CEO, tells us more about the global automotive supplier.

PRECISION AND STRENGTH

As a key player within the global automotive market, MTM Pty Ltd (MTM) has historically manufactured a wide range of vehicle products.

This broad portfolio includes handbrakes, electrical switches, door handles, automatic transmissions, steering columns, and door checks, the latter of which has surfaced as a stand-out innovation.

“In response to the industry becoming more quality-focused, we’ve started to narrow our range. As such, door checks are now our main product for the automotive market,” opens Mark Albert, CEO.

Headquartered in Melbourne, Victoria, and with a direct supply into the US and China, MTM’s products are exported globally.

“Of course, due to our international presence, which includes distribution to Mexico and Canada, our products must be able to perform in all markets and environments,” Albert details.

Therefore, MTM engages in rigorous testing when supplying well-known international brands such as Cadillac, Chevrolet, Toyota, Jeep, MG, and Roewe, to name a few.

In addition, MTM’s recent foray into non-automotive manufacturing has expanded the company’s repertoire to include a broader range of products, from external lighting systems and slide-out kitchens to electric skateboards and electric delivery vehicles.

“Customers in the industry view us as a true one-stop shop, so we’ve been able to involve ourselves in a vast range of projects,” outlines Albert.

Having ventured outside of the automotive sector in 2015, where it continues to expand, MTM is focused on seeking new customers whilst continuing to cultivate and fortify its strong existing partnerships.

STAND-OUT PRODUCTS AND SERVICES

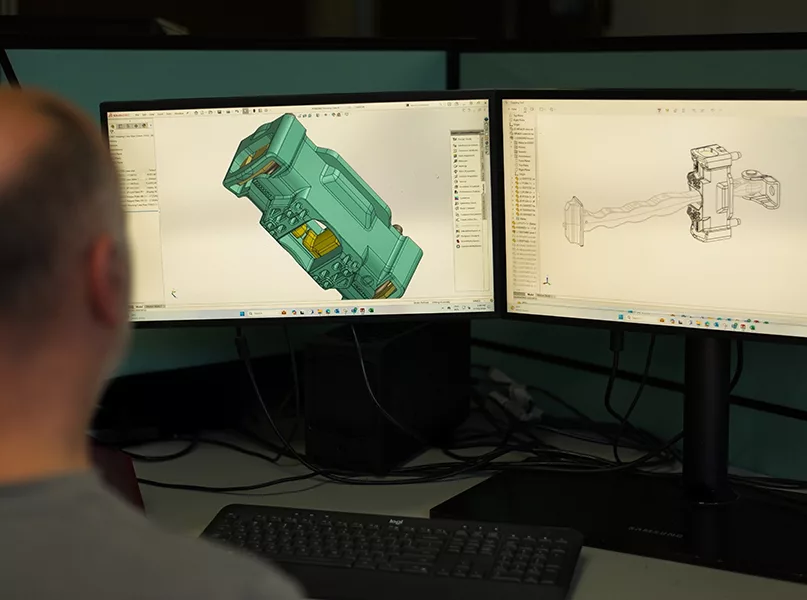

A company that prides itself on its first-rate, quality products, MTM places high importance on perfecting its operations and processes so that it can deliver excellence every time.

“We take immense pleasure in producing products that can perform in ways that none of our competitors can. To achieve this, we spend time working closely with the customer to make sure we achieve their end goals; this is our main aim,” Albert outlines.

In addition, MTM boasts a team of dedicated and skilled professionals who seek to provide expertise to customers.

“All of our staff are experts in their respective fields. Having an excellent staff base makes it a lot easier to meet customer requirements,” he posits.

In this way, MTM is confident in its ability to advise on the feasibility of customers’ projects and ideas. For example, the company is currently working on a novel product that has never been seen before on the market. In this case, the customer sought out MTM due to the company’s candid and forthright approach to project approval.

“That’s the level of trust this brand new customer has in us. If we say we can do it, we do it; if we can’t, we say we can’t –it’s as simple as that,” Albert outlines.

“All of our staff are experts in their respective fields. Having an excellent staff base makes it a lot easier to meet customer requirements”

Mark Albert, CEO, MTM Pty Ltd

PROGRESSIVE PARTNERSHIPS

Having worked closely with a number of prestigious brands over the years, MTM today is proud to partner with Cadillac, Chevrolet, MG, Jeep, and Toyota.

MTM’s relationship with the latter is particularly noteworthy. Previously, when Toyota left Australia to move overseas, MTM had not yet won an export order with the company.

However, upon receipt of a letter of recommendation from Toyota’s President, MTM realised how much support the global automotive brand provided.

“The level of support we’ve had from all of our customers and suppliers locally and globally speaks volumes of the faith that they have in us,” Albert reflects.

In the case of Stellantis, meanwhile, trust and confidence was established early on due to MTM’s historical reputation as a trustworthy supplier and automotive name, resulting in a new contract.

“Stellantis witnessed our products in the marketplace and therefore sought us out. To gain the recognition of an industry leader and household name such as Stellantis speaks volumes of the positive reputation MTM has built for itself within the industry,” he enthuses.

As a company that prides itself on not only supplier partnerships but also customer relations, MTM is able to benchmark its success based on an ability to meet their needs and the continued positive feedback it receives.

“When we go overseas, customers are so complimentary of what we do. We’ve found that North America especially often commends us highly for doing a good job, which is lovely,” he affirms.

A VAST RANGE OF PROJECTS

Although door checks are MTM’s bread and butter, the company’s foray into less familiar territory has historically provided room for growth, development, and a diversified base of customers and clients.

For example, the company recently worked on manufacturing the Tomcar, a purely off-road vehicle for the Australian market.

MTM became involved in the project as the company that contracted the Tomcar obtained the rights to manufacture it but was not well informed about the ins-and-outs of the industry.

“We completed the whole timeline in around 18 to 24 months,” he reveals.

With a simple, reliable, and uncomplicated design at its core, the Tomcar followed the mantra that ‘the simplest thing to break is the easiest thing to fix’.

However, the exciting project never came to fruition, despite MTM producing around 200 vehicles.

“As client confidentiality is paramount to us, I’m unable to divulge more about the project. I can, however, confirm that this was an exciting time, and our team were able to utilise its manufacturing expertise, in addition to the soft skills that they’ve honed over the years,” Albert notes.

SUSTAINABLE SYSTEMS

Being in the plastics industry, MTM is a company continually seeking to reduce its waste output.

“We recycle almost 100 percent of what is produced from a plastics perspective, which is a great achievement compared to where we were years ago,” Albert outlines.

In addition, each of MTM’s manufacturing plants features solar panels. As a result of this sustainable infrastructure, each plant is self-sufficient in terms of its energy usage.

“We’ve noticed many original equipment manufacturers (OEMs) asking us about clean energy in recent years, so we’re pleased to be able to inform them we can generate enough power to run our plant, in addition to many of the homes around us,” he prides.

MTM is also acutely aware of the economic benefits that accompany its sustainable practices. However, it equally acknowledges that long-term, company-wide sustainability has ultimately been implemented for the benefit of all.

“When we introduced these sustainable practices within the business, it was done with a long-term perspective, as opposed to a short-term approach,” Albert recalls.

“We of course want to garner attention outside of the automotive market, so we’re continually looking for new opportunities where our manufacturing or design capabilities can be utilised”

Mark Albert, CEO, MTM Pty Ltd

FUTURE PLANNING

As a company that has grown exponentially in recent years, MTM hopes to continue its international expansion going forward, especially in terms of the presence of its door checks in less familiar markets.

“We would like to become more prominent in Europe than we currently are,” Albert expands.

MTM’s other key target is winning more business in the non-automotive space to ensure it remains prominent in the Australian market, which has recently moved away from an emphasis on automotive manufacturing.

“We of course want to garner attention outside of the automotive market, so we’re continually looking for new opportunities where our manufacturing or design capabilities can be utilised,” he details.

As such, MTM’s focus for the future will be developing strong client and customer relationships outside of the automotive space.

“There are very few companies that have such a broad remit to provide high-quality solutions for a global marketplace. At MTM, we hope to leverage our expertise as a one-stop shop for manufacturing and design to serve a broader range of sectors,” he concludes.