Mr. Prompong Chaikul, Chairman of the Executive Committee at Stars Microelectronics, talks tackling new technologies, streamlining supply chain management and making a mark on Thailand’s flourishing electronics manufacturing market.

INNOVATION IN THAILAND

The future looks bright in the Land of Smiles.

Since the mid-1980s, electronic products have been at the forefront of Thailand’s manufacturing industries and are a key component in the country’s exports. Bolstered by private investments and the transfer of production from other Asian countries, it is unsurprising that Thailand has become one of Southeast Asia’s largest economies, second only to Indonesia. Using its own healthy economy as an anchor to its neighbouring developing countries, including Laos, Myanmar, and Cambodia, Thailand enjoys a well-earned reputation as the hub of Southeast Asia when it comes to electronics manufacturing.

Thanks to the Thai government’s acknowledgement of the contribution made by electrics and electronics industries to Thailand’s economic development, investment incentives remain an attractive prospect to major global players. The country’s well-diversified manufacturing sector accounts for 33.4 percent of the GDP.

It is calculated that various industries, primarily steel and electronics manufacturers, generated employment for 22.5 percent of Thailand’s active population in 2020 (World Bank).

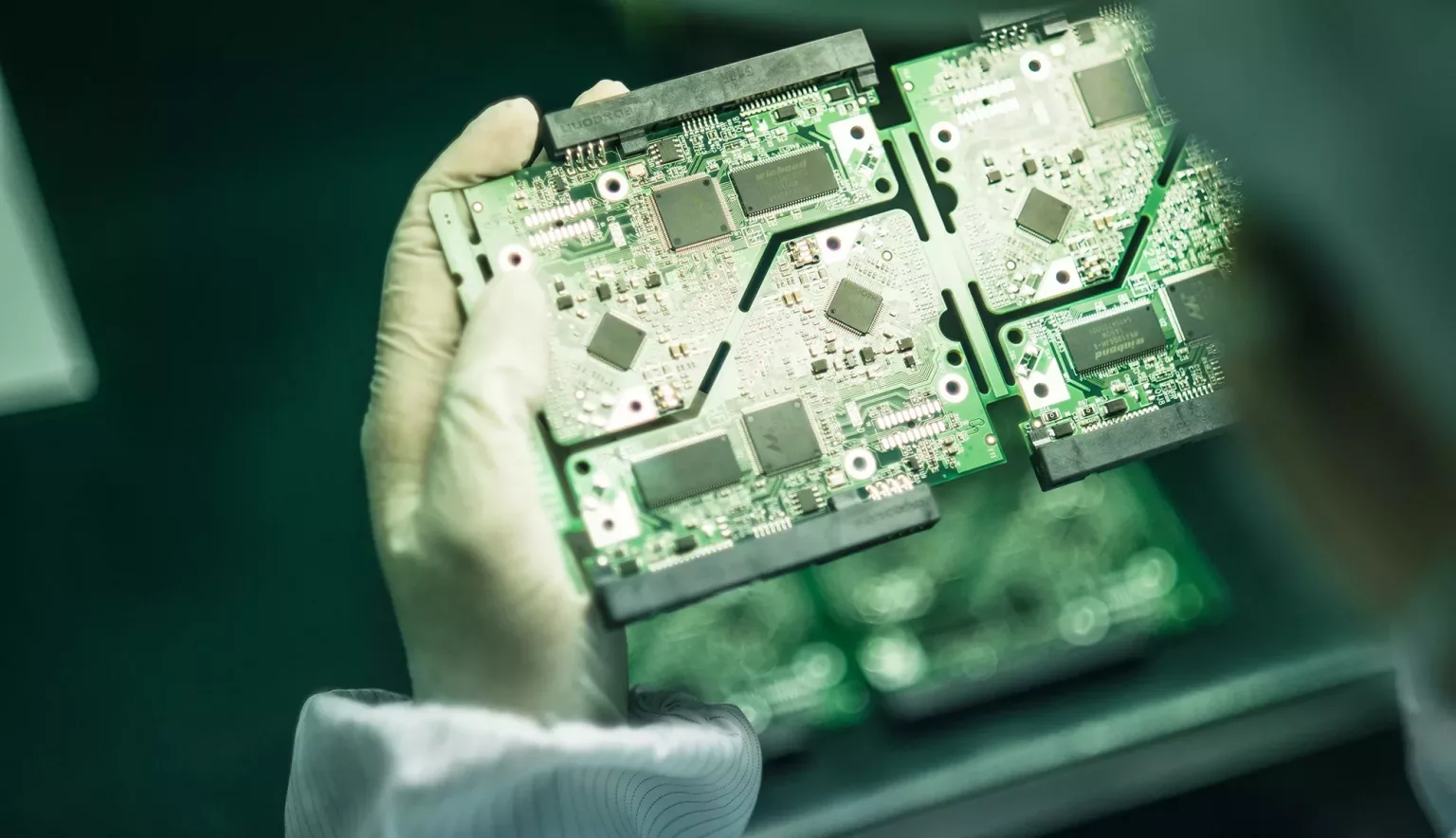

At the centre of it all sits Stars Microelectronics, a well-established contract manufacturer of electronic goods based in Ayutthaya. Providing Electronics Manufacturing Services (EMS) to Original Equipment Manufacturers (OEM) and Outsourced Assembly and Test (OSAT) customers, Stars also specialise in Microelectronics Module Assembly (MMA) and Integrated Circuit Packaging (IC).

We spoke with Chairman of the Executive Committee, Mr. Prompong Chaikul, who is in charge with production and material planning, inventory management, and supply chain management at Stars Microelectronics.

“We manufacture and assemble complex and innovative electronic components with high precision and accuracy to serve both the product’s specification and the requirements from leading global customers,” he comments.

“Products from manufacturers are able to distribute via worldwide logistics to all continents as distribution centres, with after sale service when it is required.”

Stars Microelectronics is well-suited to serve the needs of a worldwide market.

“With free-zone privileges, world-class facilities, experienced professionals and strategic infrastructure, all our products are assured to exceed customer expectations at a competitive cost,” Chaikul comments. Indeed, Stars Microelectronics aims to take the lead in the supply of medical device manufacturing services across Thailand and Southeast Asia.

“We operate under the ‘True Vertical Integration’ model, supporting our customer at any phase from design, certification, and production to after-sales service,” Chaikul says.

In his opinion, this, combined with their capabilities in handling advanced manufacturing technologies before integrating them into a completed system solution, is what gives Stars Microelectronics its edge.

“These capabilities can be demonstrated in a very limited selection of enterprises. The company is a true integrated technology to support production capabilities from semiconductor wafer level through to the electronics product system build.”

KEEPING ON TOP OF TECHNOLOGY

EMS is an industry defined by rapid advancement and constant innovation. With change at its very core, developing and adapting to the latest technologies is essential.

“Smart devices, sensors and new technology companies are racing to be the first and the best in the market every minute,” Chaikul tells us, and this relentless tide of forward development is entirely embraced by Stars’ philosophy.

“Stars is actively engaged in continuous improvement as we believe that it will bring us improved performance, organisational flexibility, and increased ability to embrace new opportunities. We look forward to continually creating new processes and adapting to new market situations,” he comments.

The advent of new products that require a higher degree of customisation inevitably impacts the supply chain, making it more complex and competitive. As such, the process of NPI (New Product Introduction), is driven to become more “rapid, robust and responsive to changes”, whilst successfully meeting the requirements of the client.

“We aim to be the company that everybody is looking up to in the industry not only because of the capability but because of technology,” Chaikul notes.

The company has fully embraced the developments of digitisation and believes in the potential for future improvements as a result.

“Stars is shooting for the stars on a nice rocket called digitisation.”

“Machine to machine communication will play a larger role in production, data analytics and availability will be crucial and an integration between ERP (Enterprise Resource Planning), MOM (Manufacturing Operations Management) and every system will have to be seamless not only at enterprise level, but throughout the supply chain to ensure that the customer demand is fulfilled,” Chaikul reflects, speaking specifically of the effect that this will have on his company.

A PROMISE OF QUALITY

From prototype, to turnkey and mass production, quality is essential at every stage of the product life cycle. The company strictly adhere to principles of Quality Management.

“Stars is a best-in-class company in Quality Management System. Our QMS is fully compatible and supports IT and ERP systems, to ensure that the products and services that we produce are material and manufacturing traceable, of the right standards or fit for a specified purpose that matches with our customers’ expectations,” Chaikul explains.

One such example of this is Star’s “Zero Defects Program” operated through Six Sigma.

“Driven on our critical operations, we create step-by-step processes that include benchmarks as we believe that well-designed processes will lead to high quality products and services,” he adds.

With a global supply chain managed by an intelligent ERP system, Stars Microelectronics endeavours to communicate security and safety in the sourcing and supply chain of electronics manufacturing. This is evidenced by the pride they take in their relationships with quality suppliers, something that, alongside partner relations, is “extremely important” and continues to be closely monitored. This developed recently with a departure from Stars’ 2020 supplier management approach, thereby enhancing the company’s strategic relationships.

“In 2021 we will implement a monthly supplier development programme to track supplier performance,” Chaikul informs us. This will enable Stars to maintain a continuous improvement to supply.

“We will also engage more key suppliers to set up a VMI (Vendor Managed Inventory) or a safety stock programme for Stars to facilitate demand fluctuations with short notice.”

LOOKING TO THE STARS

Working in such a saturated market is not without its challenges and Chaikul is explicit about the common challenges faced by all electronic manufacturing service providers; how to secure materials at the best price whilst preventing a shortage, how to minimise the transition time between each product by working with common materials on the production line, and the best way to react to customers engineering change orders that can be translated to the production in a quick and efficient manner.

“Several tools and system have been devised to combat these issues. The traditional Enterprise Resource Planning (ERP), Manufacturing Operations Management (MOM) and homebrew-customised software have been effective but may no longer be optimised for the upcoming growths and demands where everything is near instantaneous,” Chaikul informs us.

Major new investments have been launched with the company’s five-year business plan, one of which includes acquiring a new operation in Europe that will support Stars’ EU based market and supply chains.

“We are also investigating the best strategic location to expand our geographical footprint to serve our customer better while leveraging the local advantages that we have in Thailand.” Meanwhile, Stars will continue to strengthen the vertical integration pipeline, with “higher design capabilities and additional precision facilities.”

Despite the challenges experienced by industries worldwide, Stars’ refuse to let the current global situation impede their goal of becoming a $300 million company by 2023.

“Stars Microelectronics is now lined-up for an exponential growth and we are all excited for the future that we are going to create,” Chaikul concludes optimistically.

“We are embracing the transformation that is happening right now.”