MEDICINE IN MICROGRAVITY

AN ALL-IN-ONE AUTONOMOUS OPTION

The progress has been bolstered by Varda’s W-1 capsule from its W-Series, named after the Winnebago Motorhomes brand, following the completion of a drug manufacturing experiment less than three weeks after its SpaceX launch in June 2023.

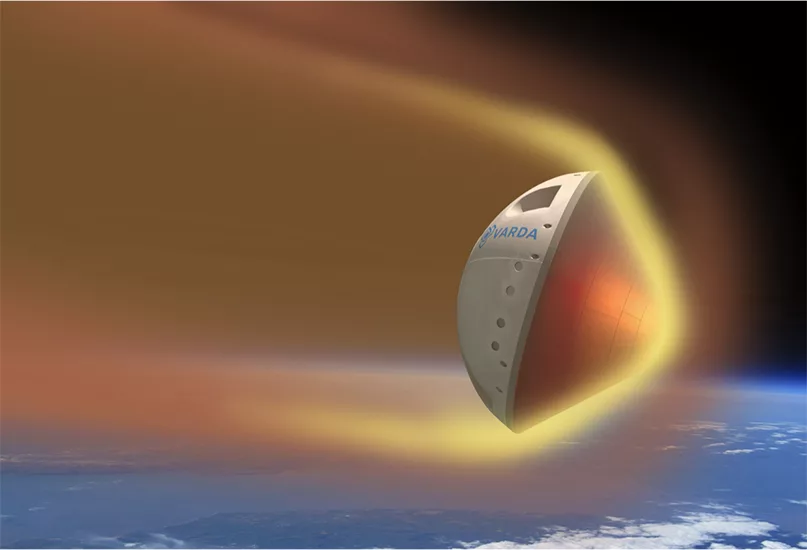

The company’s approach involves using a three-piece vehicle, which includes a spacecraft, a manufacturing module, and a heat shield protective capsule for safe re-entry into the atmosphere, completing the entire logistics chain.

The W-Series is a fleet of unique commercial satellite and re-entry vehicles explicitly designed for retrieving materials from space. Unlike other systems, it is not intended for human use, which means that it doesn’t require costly life support systems and other amenities needed to sustain astronauts.

Despite its success so far, Varda aims to make its processes more accessible and cost-effective. The W-Series is wholly independent of other space stations and capable of returning materials to Earth for post-processing, and due to frequent flights, the affordable re-entry vehicle also functions as a research platform.

Moreover, the W-Series is designed for efficient manufacturing and frequent launches and landings, making it the first mass-produced re-entry vehicle and orbital production facility in human history.

THE SPACE PIONEERING, DRUG-COOKING WINNEBAGO

The space environment provides a unique opportunity that cannot be replicated on Earth – microgravity.

Varda has developed a first-of-its-kind, cost-effective, comprehensive system that enables the impact of gravity on materials to be tested. This allows industries to leverage the benefits of space and rapidly test and generate data to advance strategic capabilities.

Processing materials in near-weightless conditions offers several advantages. This is because no convectional or sedimentational forces exist in the vacuum of space, and the absence of gravitational stresses results in the formation of flawless structures. These effects are usually locked into the material through crystallisation.

When an experiment is conducted in microgravity, it can significantly change the way buoyancy, natural convection, sedimentation, and phase separation occur.

Varda also specialises in constructing top-of-the-line processing equipment to achieve the desired outcomes, even in harsh conditions. Due to the specific limitations of working in the vacuum and microgravity of space, it is impossible to purchase materials processing equipment from a store to use in this environment.

When the process was concluded, the W-1 capsule landed in Utah on 21st February carrying the metastable Form III of ritonavir, an antiviral drug used to treat HIV and hepatitis C.

The cargo onboard contained all the essential materials required to grow ritonavir crystals. The capsule’s contents were chosen wisely, as pharmaceutical products are high-value and have the potential to kick-start the manufacturing industry beyond Earth.

BACK DOWN TO EARTH

Varda has become the third company to successfully recover an intact spacecraft from orbit. The other two companies that have achieved this feat are aerospace giant SpaceX with its Dragon vehicles and Boeing with its Starliner capsule. This is a significant achievement as it is the first time that orbital drug processing has occurred outside a government-run space station.

The conical capsule landed after re-entering Earth’s atmosphere at more than 25 times the speed of sound. It generated a stunning display of sparks, which was captured in a video and shared on Varda’s YouTube channel.

The data collected during the mission provides crucial insights into the effects of spaceflight and re-entry on the pharmaceutical process. This includes vibration, acceleration, radiation, and temperature.

Upon returning to Earth, the ritonavir crystals were sent to Improved Pharma, an Indiana-based pharmaceutical company, for evaluation.

In a post on social media platform X, Varda co-Founder Asparouhov announced that “them space drugs cooked real good” following official analyses of the space-processed ritonavir.

The next Varda mission is to encourage and facilitate the consideration of space-processed pharmaceuticals. So far, the start-up has secured USD$90 million in venture capital (VC) to carry out a series of missions in subsequent years.

Moreover, NASA, the Air Force Research Laboratory, and Varda are collaborating to conduct additional flight tests of C-PICA, which will further develop the re-entry technology, making it relevant for future missions to Mars.

Indeed, the burgeoning orbital industrial revolution is well underway and ready for take-off.