Dayton Lamina Corporation continues to be the go-to partner for all things stamping, with its combination of a rich legacy and a pioneering, forward-thinking spirit ensuring it stays ahead of the chasing pack. We find out more with Rick Hern, Vice President of Sales and Marketing.

STAMP OF APPROVAL

Sometimes the most traditional ways of doing things are the best.

When it comes to stamping, the saying ‘to stand the test of time’ certainly resonates – a manufacturing process that has been around for well over a century, with origins dating back even further depending on your interpretation of history.

It remains highly relevant today in large part due to its simplicity. In short, it is a process used to convert flat or coiled metal sheets into various shapes using forming techniques and tools such as preset dies.

However, like many manufacturing techniques and industrial processes, new ways of doing things will inevitably emerge to challenge orthodoxy, no matter how long an incumbent has been dominant.

Rick Hern is Vice President of Sales and Marketing at Dayton Lamina Corporation (Dayton Lamina), a US-born company that has deep roots in the stamping trade.

Asked for his take on the sector dynamics at present, he refers to the need to keep pace with the rate of change that has emerged from competing parties challenging the status quo.

“It can be difficult due to the numerous ways that stamping is being challenged from the likes of laser, waterjet, 3D printing, and casting,” he says.

“I also think that we don’t put enough effort, as an industry, into developing new methods, faster processes and cycle times, along with product development. These areas, in addition to marketing and training materials, are serious needs.”

Hern knows what he is talking about. His entire career has been spent in the world of cutting tools and computer numerical control (CNC), a manufacturing method that automates the control, movement, and precision of machine tools through the use of pre-programmed, embedded software.

And while he acknowledges that there are challenges ahead, there is equal cause for optimism and excitement.

“For me, this part of manufacturing, stamping, is the opportunity to take a century-old application and make it cool again,” Hern adds.

“Like CNC, there are so many things that get bent, stamped, pressed, folded… it would be amazing if the everyday consumer understood the impact of the stamping business and Dayton Lamina’s impact.”

This, ultimately, is part of Hern’s mission – to get the message out there about just how impactful stamping is and continues to be on many aspects of business, and people’s lives.

As for Dayton Lamina, there is no better organization through which that mission can be undertaken. Its origins date back to the early 20th century, with the current enterprise coming into being in 2012 when Japanese firm Misumi entered the North American market and acquired several brands. Now, it is a truly global entity with presence all around the world.

“For me, this part of manufacturing, stamping, is the opportunity to take a century-old application and make it cool again”

Rick Hern, Vice President of Sales and Marketing, Dayton Lamina Corporation

STANDING OUT AND STAYING IN FRONT

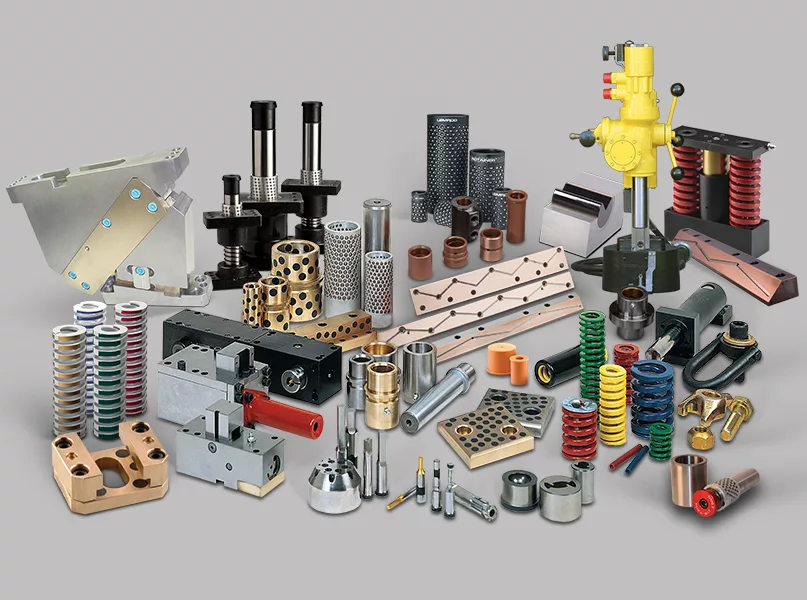

A key reason Dayton Lamina stands proud as a leader in the field is due to its ability to serve as a one-stop supplier shop to many of its customers across various industries.

The firm has a diverse customer base spanning many applications and industries – these include automotive, beverage can tooling, appliances, mandrels, nuclear fuels tooling, compaction tooling, performance racing components, ammunition, die components, and electronics, among others.

“We offer the largest, most complete assortment from a single supplier,” Hern adds. “Our capabilities to manufacture and source die components, catalog, configured and special punch tooling, as well as high precision steel of any shape, tolerance, and finish, is what sets us apart.

“For decades we have set the standard of the industry in our quick deliveries, outstanding quality, and technical expertise. This is why most automakers and other stamping companies refer to Dayton Lamina products as the trusted, specified tooling to use.”

Put simply, the company can be trusted for quality and service, a combination that sees customers coming back time after time, even those that may venture further afield seeking a cheaper alternative.

“As with many other industries and applications in B2B and B2C, customers are always looking to save a penny and find other low-cost countries or knock-off products,” Hern continues. “But they often end up coming back to Dayton Lamina because those companies stop production, cause time delays, and are inconsistent.”

A culture of continuous improvement and refinement has also been key. As Dayton Lamina has grown and added new machines and processes to produce a larger variety of parts, the operating environment naturally becomes more complex.

Recognizing this, the company has rejigged its state-of-the-art site in Michigan to ensure an optimized production flow. “In some cases, we were seeing a part traveling a mile by the time it was complete,” Hern says. “Now, we’ll be able to cut that to 20 percent of what it was.”

MOVING WITH THE TIMES

Continuous improvement also means investing in technology to augment the vast depth of human experience and knowhow contained within the organization.

“For decades, we have relied upon operator skill to hold tight tolerances running multiple machines at once and CNC tooling with manual load and unload – this is mostly due to keeping costs down, and the fact that the manufacturing processes is proven, and operators know the parts,” adds Hern.

“In today’s environment we are addressing ever changing needs to be more cost effective, use less manpower, and operate overnight and at weekends unmanned. Automation also enables us to run several parts with little to no setup changes, and reduce lead times, costs, and human intervention.”

Such investments are being made at several sites. In Bellaire, new robotic part changers are being installed. At Dayton, new CNC grinders are about to come online. Meanwhile, the Beaver Dam facility is about to benefit from the introduction of a new spring manufacturing machine.

Coming back to Hern’s remit as Vice President of Sales and Marketing, a key recent priority has involved Dayton Lamina’s brand refresh – another sign that the organization continues to move with the times.

That said, the tried and tested product range is not being touched. Rather, the rebrand is designed to bring cohesiveness to the portfolio as a whole, the ultimate aim being for Dayton Lamina to have its own identity as the complete solution provider and technical leader.

A smarter, more intuitive website is central to this endeavor.

“We’re adding more info, more access, and more tools,” Hern says. “This new system connects directly to our manufacturing capabilities as well as our ERP system to show specific customer orders, history, pricing, and inventory levels.

“It will enable our customers and distributors to manage their orders, search for products and 3D CAD drawings which we’re introducing. Historically, we’ve had a limited amount of products with CAD drawings, so this will be a big and positive change.”

This feeds into Hern’s key goal for the year ahead, which is to make the ordering process as seamless as possible for Dayton Lamina customers. It is a transition which will also require training and development with internal teams, as well as continued investment in technology behind the scenes – all crucial steps in the journey ahead.

DAYTON LAMINA CORPORATION PARTNER