KNF Flodos AG delivers quality engineering, meticulous design, and outstanding innovation in diaphragm pump technology. We discover more with Chief Marketing Officer, Michael Davies.

DELIVERING UNMATCHED PROFICIENCY

Our aim is our customers’ success, now, and in the future.”

As a firmly established leader on the world market for diaphragm pump technology, KNF Group operates multiple R&D departments with the goal of continuously pushing technology further in the diverse realm of manufacturing.

KNF Group was founded in 1946, in Freiburg, Germany, and is still proudly family-owned to this day, as it continues to develop, produce, and distribute high-quality diaphragm pumps and systems for gases, vapours, and liquids.

Now able to rely on five competence centres for development, design and production, KNF Group’s facilities are located in Germany, Switzerland, France, and the US.

Occupying a vitally important strand of this highly successful operation within the vast KNF Group umbrella, is KNF Flodos AG, which acts as the broader group’s diaphragm liquid pump specialist. Since its inception in 1987, the company has consistently developed and produced innovative, high-quality products for the international market.

“We serve a diverse mix of customers in various industries, such as medical technology, digital printing, semi-conductor and fuel cells,” introduces KNF Flodos AG’s Chief Marketing Officer, Michael Davies.

In the face of an onslaught of turbulence throughout the industry, which has seen many companies face strong challenges especially in the supply chain, caused by the COVID-19 pandemic, Davies remains refreshed and upbeat about the current state of the manufacturing landscape across Europe.

“Despite all the doom and gloom and talk of disaster every time you open the newspaper, we remain very optimistic and so do the majority of our customers, as we have grown considerably over the last two years,” he describes.

“Despite all the doom and gloom… we remain very optimistic and so do the majority of our customers, as we have grown considerably over the last two years”

Michael Davies, Chief Marketing Officer, KNF Flodos AG

QUALITY MANUFACTURING GUARANTEED

Over the years, KNF Flodos AG has enjoyed a record of steady growth while also broadening its experience and global reach. The company is constantly expanding its multi-industry expertise and growing an enviable range of applications.

From the reliability of its impressive product portfolio and solutions to its watertight promises of both quality and delivery, KNF Flodos AG is entirely dedicated to helping its many clients meet their manufacturing goals.

The pump is often a critical component in the customer’s system and thus a reliable function which is very important to them.

Many applications benefit from the use of diaphragm technology as it effectively prevents media contamination and ensures excellent leak-tightness for media transfer. The diaphragm pump is ideal for use with gases and liquids being able to run dry and self prime. With liquids, the diaphragm pump is self-priming and safe to run dry, whereas alternatively, when used with gaseous media, it is resistant to both moisture and condensation.

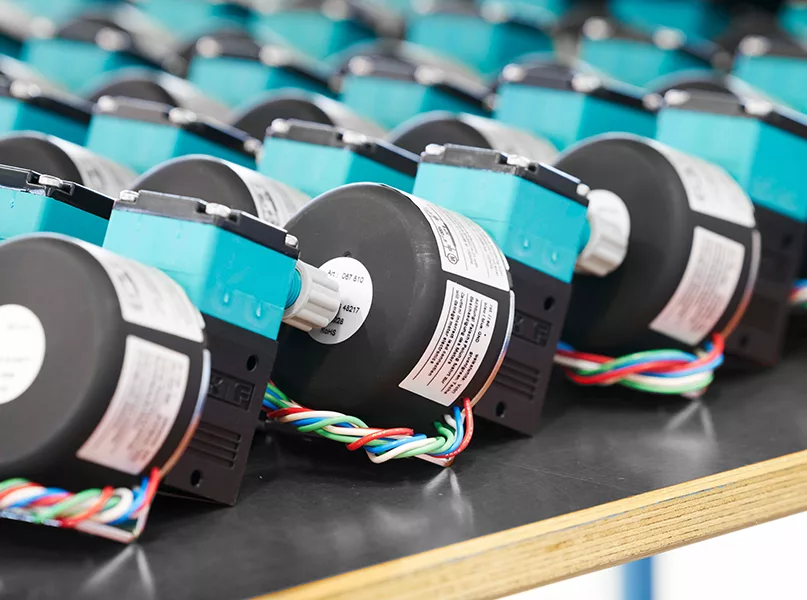

Complementing this expertise, KNF Flodos AG enjoys the advantage of having three product centres within close proximity between Germany and Switzerland. These international facilities work effectively to synergise operations and processes to mutually benefit each other.

“If one of our facilities is developing a new motor, for example, we’ll talk about it and exchange key information. New rubber parts, elastomers, plastics or anything that one of the product centres discovers can then be shared around and this provides strength to the group through a joint effort and improved cohesion,” details Davies.

AT THE CUTTING-EDGE

Embracing and utilising innovation for KNF Flodos AG means remaining open-minded about new and different approaches.

Drawing on the company’s collective expertise across a multitude of varied fields within the engineering industry, from mechanics, materials, and fluidics to electronics and software, KNF Flodos AG strives to always find the smartest solutions for every application – not just for the present, but also for all its customers’ future needs.

“Over the last four years we have brought out a whole new smooth flow pump range. One of the disadvantages of the diaphragm pump technology was always the pulsation created on the inlet and outlet side. The new pumps have kept all of the strong USPs of our technology and managed to solve this issue, allowing us to move into a wide range of new applications,” Davies describes.

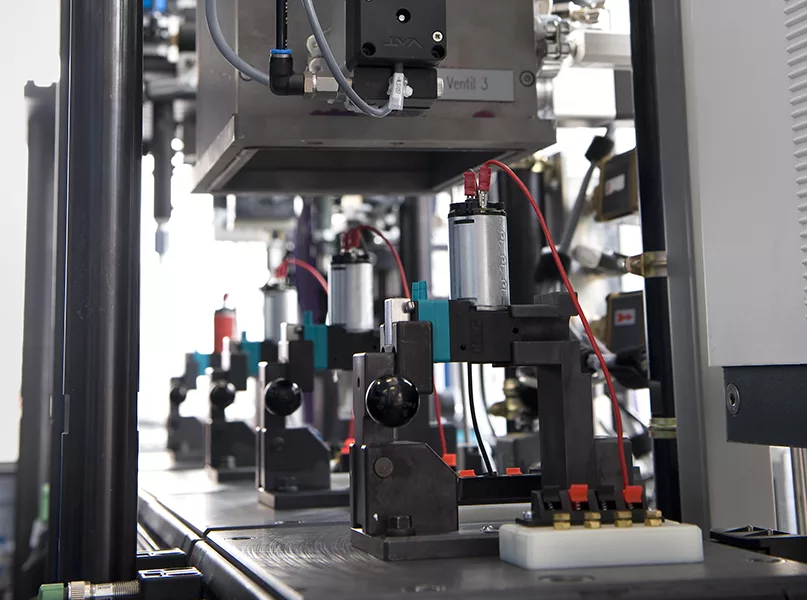

New products are manufactured at KNF Flodos AG’s site according to the highest quality standards, and the close cooperation between product engineering, production, and sales also enables the company to react rapidly and on a personalised and individual basis to any specific customer requirements or local market demands.

Guided by an unwavering spirit of innovation and based on comprehensive production and application knowledge, the company’s cutting-edge production ensures the continuous optimisation of pump technology and manufacturing ability at the highest level.

Wherever its customers require the company’s services, KNF Group has established a worldwide presence and is always ready to take care of specific application requirements. These sales centres are found at 24 locations worldwide and enable the group to serve all its consumers with a flexible, fast, and individual approach.

DIGITALISATION AND AUTOMATION

Digitalisation is an ongoing process which most industries have embraced and continue to develop as a way of streamlining operations, saving valuable time during a variety of processes, and transforming data collection and analysis. It is an ongoing focus for KNF Group as a whole, as it looks towards a new era of smoother processing and achieving new heights of customer satisfaction and product optimisation.

“We initially started the entire digitalisation process about two or three years before the pandemic hit. I have to say we were very lucky that we had it all in place when COVID-19 fully started to affect the industry,” recalls Davies.

Other companies within the manufacturing sector and elsewhere that had not yet started the process of going digital had more time to adapt to the situation during this difficult period.

“We continue to test every single pump that leaves the factory, and previously those results were written on a piece of paper, so that’s something we’ve really left behind in the last few years as all the data is now digitally inputted on the computer,” he adds.

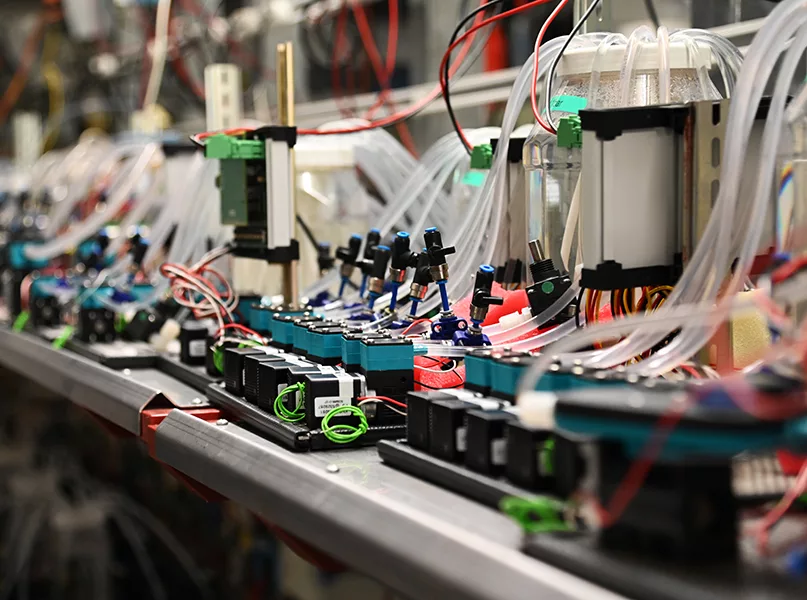

Automation is another process that KNF Flodos AG has been exploring in order to enhance quality control and efficiency. The company continues to push technology further as production quantity demands continue to rise. Starting off as a more niche producer, KNF Flodos AG now undertakes many large-scale orders where the same level of quality needs to be ensured independent of lot size.

“Investing in automation is a vital part of our growth strategy, allowing us to ensure a high level of process quality and efficiency,” Davies affirms.

“If you’re building two pumps, then people tend to take a lot of care over building them to perfection. However, if someone needs to build 50,000 pumps, mistakes become more likely. So, the question became, how can we build a large, monotonous quantity of the product and still be able to ensure the same quality? This is where we turn to automation.”

ENHANCING A SUSTAINABLE FUTURE

Sustainability and environmentally responsible behaviour have and will continue to play a major role at KNF Flodos AG. One way in which the company is looking to secure a greener future has been the implementation of several environmental renovation measures at the company’s facility in Sursee, Switzerland.

“About three years ago, we covered our roofs with solar panels and 10 years ago we were one of the first companies to use geothermal heat. By drilling a hole in the earth, we now pump water down and it comes up warmer; because of this, we can now heat our building in the winter and cool it in summer with this much greener process,” explains Davies.

From now on, the location will generate part of the electricity it consumes itself, use energy even more efficiently, and additionally stabilise a nearby nature reserve with water.

This initiative aims to continue generating renewable electricity, and to achieve the optimal solar yield, these solar panels were installed in an east-west orientation, covering about one-third of the location’s electricity needs.

Elsewhere during this modernisation process, two parking lots were also each equipped with a charging station so that the subsequent electricity generated can be used for electric mobility. Four more charging stations will be added soon, and the company’s car fleet is currently changing over to electric.

After many years of dedicated work and a wealth of gained expertise, as well as embracing these enhanced sustainability initiatives, KNF Flodos AG has established itself worldwide as the leading liquid pump innovator.

“Going forward we want to continue to win new customers, push diaphragm liquid technology, and be the ultimate technology leader”

Michael Davies, Chief Marketing Officer, KNF Flodos AG