Since the privatisation of Serbia’s copper industry, manufacturing companies such as Copper Mill Sevojno have gone from strength to strength.

COPPER STANDARDS

Copper is an element with a long and fascinating history.

One of the first metals to be extracted and used by humans, it has been found in coins and ornaments dating back to 8000 BC. It was copper tools, forged in around 5500 BC, that enabled human beings to emerge from the Stone Age.

Thanks to its malleable, anti-corrosive and heat and electricity conducting properties, copper is as important in the present day as it was to early humans.

It is currently used in construction, power generation and products such as smartphones, televisions, computers and electric motors. Furthermore, putting copper surfaces on high-touch surfaces in hospitals can reduce infection transmission, thanks to its anti-microbial properties. Recent research has shown that the coronavirus – which survives for days on glass, plastic and steel surfaces – lasts mere hours on a copper surface.

In Serbia, the copper industry is going from strength to strength. Mines, smelters and processing plants have been undergoing a process of privatisation since 2000, which involves restructuring and significant investment cycles.

“We have witnessed the entry of the big players into the market through acquisition of local companies, as well as great performance of the local companies, which have managed to focus on export-oriented production, thus becoming dominant regional players.

“Our copper industry is tightly related to the European copper industry. Since Europe is the second largest consumer of the copper, there is significant market potential for Serbian export of copper and copper products and specifically for Copper Mill Sevojno.”

These words are spoken by Nebojsa Ciric, CEO of Copper Mill Sevojno (also known as Valjaonica bakra Sevojno, or VBS), a Serbian company which produces copper and brass products.

Ciric has enjoyed an interesting and dynamic career which led to his current position. Upon completing a degree in Management and Economics at the London School of Economics, he returned to Serbia and spent a decade working as Director of Financial Services for Deloitte Central Europe. This was followed by a stint serving the Serbian government as State Secretary for Economy from 2007 to 2012.

“My main objectives and activities were focused on creating economic policies directed towards macroeconomic stability, investment policies and programmes, austerity measures during crisis period, including improvement of Serbian business and investment environment,” Ciric explains.

“After my wholesome and enriching career in the government, I decided to shift my career to the real economy, to a sector such as manufacturing. An opportunity presented itself in 2014, when I was asked to join the East Point Holding Group as the Chief Executive Officer.”

At the time, the organisation consisted of a group of companies with diversified business lines: copper production (Copper Mill Sevojno); silos and milling (Zitomlin); and an industrial bakery (Klas/BPI). Ciric’s task was to restructure the group, which was then in what he refers to as a “financially distressed situation”.

70 YEARS AND STILL GOING STRONG

These days, VBS is a prosperous business employing almost 1,100 people.

It produces copper and brass products which it exports across European countries – including Germany, Italy, Austria and Belgium – as well as to North America, Middle East and Russia.

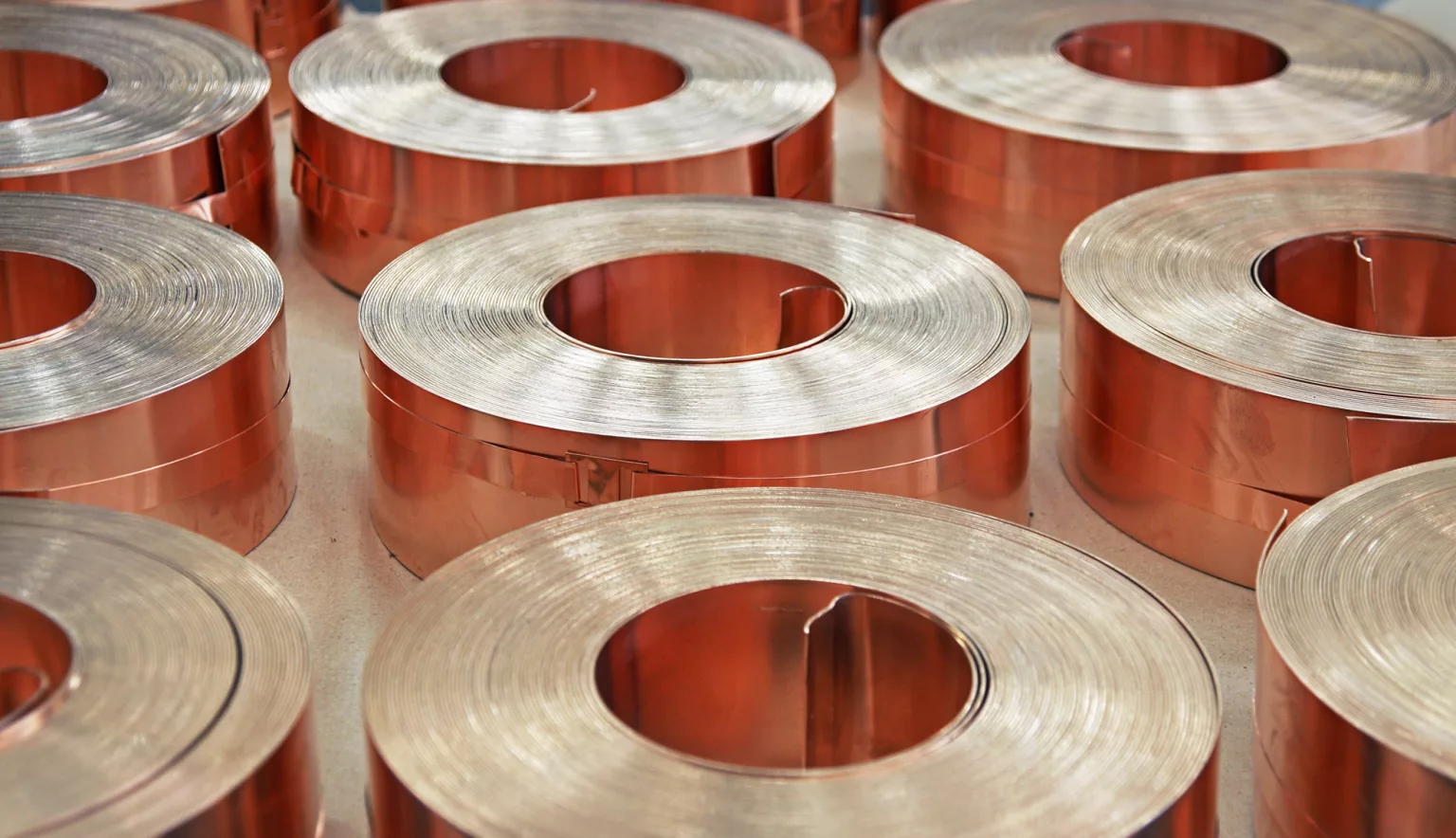

It has three major production segments – foundry, rolling and extrusion mills – enabling it to offer its customers a large variety of high-quality products. Sheets, foils, plates, discs, bars, rods, wires, tubes and much more can be purchased in a single order. Its industrial consumers (those in the automotive, electrical, medical and general industries) account for 80 percent of products sold, with the remaining 20 percent made up of construction industry consumers.

“VBS is the leading domestic player in the Serbian copper processing sector, holding 65 percent of the market share, and a competitive player in the European market. The company has no similar competitors in terms of product assortment and production capacities, domestically or regionally,” the CEO says.

One reason for the company’s current success comes from its 70-year legacy.

VBS started production in 1952, initially producing 25,000 tonnes of copper per year. Capacity was soon raised to 60,000 tones per annum, and it wasn’t long before the factory became the largest processor of copper and copper alloys in former Yugoslavia. In 2004 it was transferred to private ownership, and a comprehensive investment cycle was implemented, which improved the factory’s technological capabilities and subsequently enhanced product quality.

Being in operation for so long has enabled VBS to create an established client base across both domestic and regional markets, as well as develop long term relationships with its customers.

“Throughout its history of 70 years, the company has established and demonstrated its strong and proud legacy, confirming the high quality of our products, excellent and dedicated employees, an appropriate management model and continuous improvement in operations, even during challenging times,” Ciric says.

“We are more than proud to be part of this ongoing story of success and strongly believe that years ahead of us will be even more successful and fruitful for all our employees, but also for our customers and clients.”

A CARING COMPANY

Alongside maintaining strong relationships with customers, the company also benefits from long-term relationships with suppliers.

Its primary copper cathode supplier is Zijin Bor (formerly RTB Bor), a domestic company with whom it has a decades-long cooperation. It also has long term contracts with its other suppliers of zinc, copper and brass, thereby ensuring stable dynamics and metal inflow, as well as diversification of risk. Copper products do not generate high profit margins (the standard EBITDA margin for the industry is between five and 5.5 percent), meaning that a seamless supply chain is necessary.

“The supply chain can have a significant, if not crucial, influence on the financial performance of VBS,” the CEO explains. “We have recognised the importance of continuous work on establishing and expanding our stable base of suppliers of both primary and secondary raw materials, which has brought positive effects on margins, savings in production and overall better EBITDA figures.”

The company also looks beyond customers and suppliers to establish strong relationships with both its employees and the local community.

“Since being founded, our company has played an important role in the development and wellbeing of local community,” Ciric says. “We have taken part in numerous infrastructure projects, locally and regionally. We are the sponsors of the local football club and several local artistic societies.

“Moreover, we financially support local health and education institutions and local religious communities. We are proud to point out our support for the Paralympic Association of Serbia and their excellent results at the world competitions in 2019 and 2020.”

The company rushed to help its community during the COVID-19 outbreak, donating funds towards an ambulance for the local hospital. It has also set up a medical fund for current and former employees. Even before the pandemic, it took great pains to look after its employees’ health, safety and wellbeing.

PRESENT CHALLENGES AND FUTURE OPPORTUNITIES

The copper industry has, of course, been impacted by coronavirus, as has VBS itself.

Some of its buyers have ceased operations, there have been temporary stoppages of truck transport across the EU, health and safety measures to implement and a reduction in sales, to name but a few.

“Generally, conducting business has become more difficult and we have experienced uncertainty in the country, in the region and of course globally. I think that we have to recognise the fact that we will need to accommodate to the new circumstances living and working in the world with coronavirus for some time in the future,” Ciric says.

In the short term, VBS is devoting all its efforts to overcoming the strictures caused by the pandemic, trying to ensure the least possible damage to its operations and to prevent a drop in results and performance. However, as the conversation draws to a close, Ciric outlines an ambitious five-year investment plan that the company is soon to roll out.

“After more than a decade since the last major investment took place, we have prepared and are ready to execute the investment plan of around €15 million in total, which primarily relates to the upgrading of the existing machinery, modernisation and automation, new equipment and machinery, improvements in final product quality, expansion of capacities and improved environ-mental protection,” he explains.

The rolling mill will see an investment amounting to around €9 million, while the remaining €6 million will be divided between the extrusion mill, foundry and quality control.

“Based on our forecasts, upon the execution of the full investment program, the positive cash impact will be on average one to two million euros annually,” Ciric adds.

“More importantly, aside from the financial impact, the investments will secure the stability of the machinery and equipment and the entire production process in the long run, improve the quality of our final products, reduce claims, and further increase customer satisfaction.”

Furthermore, the new technology will be more energy-efficient, reducing VBS’s total emissions and enabling it to contribute to environmental protection.

With its 70-year legacy, commitment to long-standing partnerships and high-quality products, VBS looks set to be spending many more decades in fruitful operation.