As one of the world’s leading manufacturers of forestry equipment and solutions, Komatsu Forest’s ability to offer quality, peace of mind, knowledge, and support to its customers is unparalleled. Jens Bengtsson, CEO, discusses the company’s dedication to both sustainability and continuous innovation.

SUSTAINING THE FUTURE OF FORESTRY

Founded in 1921, global equipment manufacturer Komatsu originates from the Japanese city of the same name – home of the former copper mine, Yusenji, which was once vital to the local community’s economy.

When Meitaro Takeuchi, Komatsu’s Founder, assumed ownership of Yusenji, he became aware that the mine’s copper deposits would soon run out.

However, rather than abandoning the development, he pre-emptively funded projects to upskill the local community, including Komatsu Iron Works – a machinery company for the maintenance of mining equipment.

Today, guided by Takeuchi’s principles – quality first, technology innovation, globalisation, and development of people – Komatsu serves multiple industries as one of the world’s leading manufacturers of forestry, construction, mining, and utility equipment.

Takeuchi’s commitment to local communities remains at the company’s core, influencing everything from the way it thinks about innovation to its onboarding processes and customer relations.

“Ever since the founding of our company, it has been important that we contribute to answering the needs of society, both today and for generations to come,” opens Jens Bengtsson, CEO of Komatsu Forest.

Manufacturing equipment and products for professional forestry use worldwide, Komatsu Forest, a subsidiary of Komatsu, headquartered in Sweden, provides end-to-end solutions throughout the forestry lifecycle.

Reflected in its evolution as a truly global company with an extensive and diverse workforce, Bengtsson believes that when the people of Komatsu are united by a common goal, the remarkable can happen.

“We believe that value is best created together, and we accomplish more when we factor people, businesses, and the planet into our decisions,” he adds.

As such, due to the rich heritage and underpinning values that the entire group has carried forward for over 100 years, Komatsu Forest is a company poised for success.

INDUSTRY EVOLUTION

Over the years, the European forestry industry has witnessed significant evolution.

Today, sustainable forestry management and timber harvesting, such as that carried out by equipment produced by Komatsu Forest, is seen by many as a realistic solution to the use of fossil fuels and single-use plastics.

“Forestry is an essential business for the lifestyle we lead but also a major contributor to the necessary transition from fossil fuels to more sustainable materials – for example, exchanging plastics for paper or concrete for wood,” Bengtsson outlines.

The global shift towards limiting single-use plastics is very much ongoing, with raw forestry materials undeniably crucial in supplying alternatives.

However, trees themselves have also become increasingly valued and safeguarded for their role as essential contributors to the environment, from biodiversity to climate change mitigation.

As such, a wide range of EU policies have emerged to protect European forests and sustain their environmental benefits, including the EU’s Forest Strategy for 2030, Biodiversity Strategy, Nature Restoration Law, and Renewable Energy Directive (RED).

Specifically, the Paris Agreement, which sets out to cut global carbon emissions, directly benefits from living trees as essential mitigators of carbon dioxide (CO2).

“Standing forests are needed to sequester CO2 and thus contribute to achieving the Paris Agreement’s climate goals. As a result, we see new regulations for forestry coming into place all the time,” Bengtsson points out.

Komatsu Forest recognises how both the modern forestry industry and the safeguarding of European forests are important developments that should be supported and believes that they need not be opposing factions.

The company contributes to this equation by developing forestry solutions that can support and contribute to the environment during the full forestry lifecycle.

“For sustainable forestry that will continue to add value for generations to come, we believe that forests need to be managed and maintained considerately so that it can keep providing the valuable raw materials,” he confirms.

MINIMUM EMISSIONS, MAXIMUM ADAPTABILITY

To achieve holistic management of the entire forestry cycle, Komatsu Forest, including subsidiaries, offer start-to-finish equipment and solutions, from planting through to thinning, final felling, and logging.

Generally, there are two main methods for logging, cut-to-length (CTL) and full-tree. Komatsu Forest produces CTL machines at its production facility located at its headquarters in Umeå, Sweden.

“Forests can look very different around the world, from hardwood to softwood, to large and small stems, from natural forests to plantations, from hilly terrain to wet ground, and from thinning to final felling,” Bengtsson observes.

To cater to these differences and accommodate clients’ various requirements across the globe Komatsu Forest has developed its product line accordingly.

“For CTL, two types of machines are used in a pair,” he explains.

Komatsu Forest’s harvester, which consists of a base machine and a harvester head attached to it, first cuts the trees to a length specified by the sawmill, before a forwarder gathers the logs and forwards them to the roadside.

The company’s suite of CTL products ranges from small, nimble harvesters to versatile all-rounders for different types of logging as well as final felling machines.

By offering a broad range of harvesters, harvesting heads, and forwarders compatible with one another, Komatsu Forest is able to provide its clients with maximum adaptability.

Furthermore, each piece of equipment can be fitted with technology and smart digital solutions designed to simplify working in the forest whilst contributing profitability and productivity.

Whilst Komatsu Forest’s vast suite of products is already considered advanced, it constantly seeks continuous improvements to its reliability and performance to remain at the forefront of the industry.

For example, the Komatsu C124 harvesting head has recently received significant upgrades, including a valve block and enhanced hydraulics for the feeding system.

Following the head’s recent exhibit at major Finnish heavy machinery event, FinnMETKO 2024, Komatsu Forest reports overwhelmingly positive reviews from test customers who noted its smooth operation and efficient feeding.

CARBON NEUTRAL BY 2050

Sustainability has played an important role throughout Komatsu’s history and today continues to empower its vision for a sustainable future where people, businesses, and the planet thrive.

Thus, it seeks to achieve carbon neutrality across the group by 2050.

“As much as this is an ambitious target, it is very much in line with our purpose and we have a strong dedication to achieving this,” Bengtsson reflects.

One evident contribution to this sustainability target is Komatsu Forest’s new production facility in Umeå. In designing the factory, the company had two important objectives – to build a production facility that focuses on both the environment and workplace.

In accordance with the Sweden Green Building Council’s Miljöbyggnad (MB) certification system, the facility meets its Environmental Building Gold Standard, for which stringent criterion based on energy efficiency, building materials, and indoor environmental quality must be met.

“We had the privilege of starting with a blank sheet when designing our new factory, which meant we could install geothermal heating and solar cells to ensure we use renewable energy,” Bengtsson reveals.

By improving its working processes within the facility, Komatsu Forest has been able to reduce the number of wheel loaders in operation, whilst all working vehicles are fuelled with hydrotreated vegetable oil (HVO), a fossil-free, renewable alternative to diesel – all of which has contributed to achieving carbon neutral production.

“It is rewarding to see our sustainable vision coming to life in our facility, where approximately 650 of our employees spend their working days,” he prides.

The next milestone for Komatsu Forest is reducing emissions from its machines. Whilst the concept of electrification in forestry is certainly a groundbreaking technological leap forward for the company, it also poses major challenges.

Since its machines work off-grid, there are many aspects that Komatsu Forest must consider as it sets out to develop this machinery.

“For our machines to be able to use different types of energy media, power distribution solutions will be required to achieve such a workplace in a forest setting,” Bengtsson advises.

“Ever since the founding of our company, it has been important that we contribute to answering the needs of society, both today and for generations to come”

Jens Bengtsson, CEO, Komatsu Forest

SMART FORESTRY

A major part of accomplishing sustainable forestry management is maintaining an awareness of the environmental impact of the processes involved.

Naturally, practices such as logging can lead to major changes in a forest’s natural composition, which is why thorough planning must be conducted to ensure this is carried out with care.

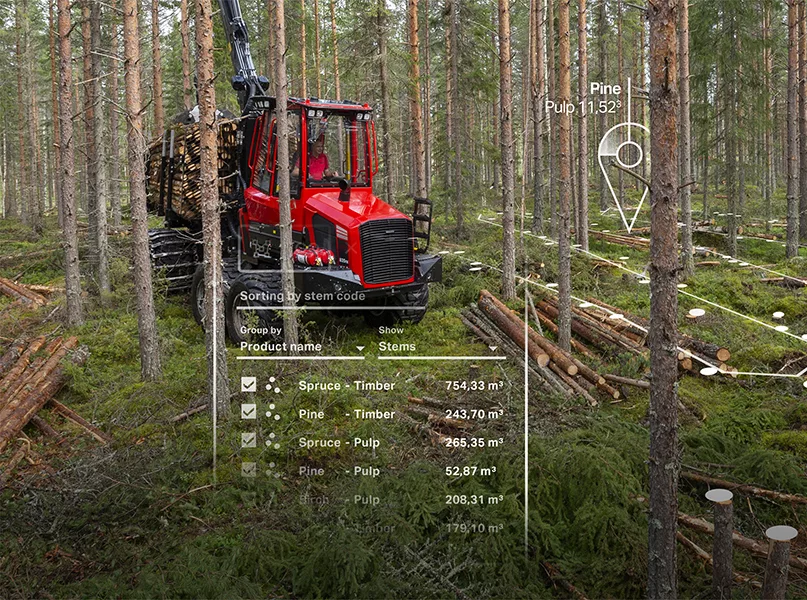

“To facilitate both the contractor and operator with precise planning, we offer Smart Forestry,” Bengtsson tells us.

A collection of digital solutions, Smart Forestry helps contractors to perform operations in a smart, productive, and sustainable way.

Whether dealing with a large or small fleet, Smart Forestry allows contractors to utilise a large amount of data from machine operations to make informed decisions.

“Smart Forestry currently encompasses three unique applications: Smart Forestry Fleet Monitoring, Smart Forestry Vision, and Smart Forestry Precision,” he surmises.

Smart Forestry Fleet Monitoring utilises geographic information system (GIS) data and mapping technology to plan safe routes for harvesters and forwarders alike.

It also allows operators a comprehensive overview of their machines as it gathers data on fuel consumption and production, with all information logged and stored automatically.

“The ability to plan harvesting assignments remotely, alongside remote-control functions, is a major benefit.”

The Smart Forestry Vision application, meanwhile, enables operators to access layered information on a map, such as operating status, whilst it is able to share information between functioning machines at any given site in real-time.

Last but not least, Smart Forestry Precision is the company’s newest and most advanced application, providing access to a new range of possibilities.

Utilising the latest satellite positioning technology, it can determine a machine’s exact position with a margin of error of just a few centimetres.

“By being able to pinpoint a machine’s location so precisely, functions to greatly simplify the operator’s working day have emerged,” Bengtsson excites.

For example, operators can create digital boundaries around a work area and receive warnings if a machine comes too close to this boundary, which is very useful when making nature considerations.

Furthermore, thanks to the high precision offered by this technology, machine tracks and stem codes can be visualised, showing the exact position of processed logs.

“At Komatsu, we see ourselves supporting the industry through our advanced machines and helpful digital solutions,” he asserts.

“At Komatsu, we see ourselves benefitting the industry through our advanced machines and helpful digital solutions”

Jens Bengtsson, CEO, Komatsu Forest

COMMUNITY-ORIENTED

Just as environmental responsibility is an essential part of how Komatsu Forest views the world and conducts its business, so is corporate social responsibility (CSR).

Both inform the ‘Komatsu Way’ – a company culture that prioritises safety, quality, and continuous improvement, and always puts the customer first.

“We aim to contribute to society by answering their needs today and for generations to come,” Bengtsson states.

Examples of Komatsu’s CSR include clearing anti-personnel landmines in Cambodia and providing community development support in the Southeast Asian country, demonstrating its strong contribution to society.

Closer to home, Komatsu Forest has focused its efforts on education, including upskilling college students.

“A little more than 10 years ago we saw a sharp decline in applications to technical colleges,” he reports.

Drawing on this statistic, Komatsu Forest recognised how its local educational institutions were not well equipped, whilst the female-to-male ratio amongst technical students was poor.

Therefore, to curb this declining trend, it made a substantial donation to a local school, Dragonskolan, so it could invest in equipment and uplift the status of its technical education.

“Our donation serves to support continuous upgrades of the school’s equipment for the next 10 years and thereafter, whilst we also offer yearly scholarships to students,” Bengtsson elaborates.

Though the scholarship programme, select students are able to visit Komatsu’s headquarters in Japan to bolster their technical education.

AN INNOVATIVE FUTURE

Over the years, Komatsu Forest has received many accolades and recognitions, including the recent KWF-Tagung Members Award for Forestry Innovation, awarded in June 2024.

“It is always rewarding to be recognised for our work and especially our innovative products, since this is an integral part of who we are,” Bengtsson imparts.

The company is also keen to emphasise the importance of its dedicated staff in achieving such awards.

“We are very thankful and consider the KWF-Tagung Members Award for Forestry Innovation as a token for all our employees’ dedication.”

Awards aside, Bengtsson points out that the best recognition the company could receive is from its employees and customers, many of whom spend most of their working life using Komatsu Forest products and machinery.

“Earning that trust and creating those long-lasting relationships is the best reward we could ever earn,” he concludes.

Going forward, the company seeks to continuously improve its suite of products, which is reflected in recent updates to the Komatsu 895 forwarder.

Its strongest forwarder yet, the Komatsu 895 combines a powerful transmission with a brand new 205F crane, capable of carrying loads weighing up to 20 tonnes.

Equipped with the newest Smart Forestry technology, the forwarder is also both durable and smart.

Smart Forestry is very much an ongoing development that continues to evolve, with Komatsu Forest implementing updated features to the suite of existing applications as new technologies come to the fore.