Attentive customer service, innovative design and superior quality run at the core of B&R Enclosures. We discuss advanced manufacturing and an Industry 4.0 future with Co-CEO Ben Bridges.

DESIGNED TO PROTECT

Proudly Australian, independent, and family-owned and operated for over 65 years, B&R Enclosures (B&R) holds a reputation of excellence.

As Australia’s largest enclosure manufacturer and electrical equipment integration specialist, B&R is well-established as an industry leader in the design and manufacture of enclosure and cabinet solutions.

“We provide complete enclosure solutions for the protection of equipment and the safety of people who install and operate them,” introduces Co-CEO, Ben Bridges.

The wide-ranging and expansive portfolio of B&R’s product offering – with over 1,000 standard enclosure types suited to a myriad of applications – is complemented by its ever-growing footprint. Although its headquarters, branches and manufacturing facilities are spread primarily across Australia, B&R also hosts offices in Asia and the Gulf.

“We support our growth by being a manufacturer that operates well within the markets we service. This often means we have an advantage over businesses that are manufacturing in distant locations.

“We are a good-sized operator, able to effectively manufacture products in shorter runs than many competitors.”

With the four core virtues of quality, innovation, service and value fuelling the company’s growth and successes, B&R offers standard and customised enclosure solutions catering to applications in process automation, power distribution and control, switch disconnection, junction and marshalling, motor control centres, climate control, data and communications.

Supporting this diversified and varied offering are five separate divisions united under the B&R umbrella: Hazardous Areas, Industrial, Residential/Commercial, Data ICT and Defence, with each offering a bespoke approach to its respective market segment.

“Together these divisions share the strengths, resources and experience of the founding company to provide attentive customer service, innovative design and superior quality,” continues Bridges.

B&R is a company that doesn’t shy away from challenges. This is evidenced by the decades that B&R has spent working with the mining industry, and its success and experience in delivering solutions in challenging environments. Mine sites are typically located in remote environments and exposed to elements that can be ruinous for equipment, B&R responds to this need for reliable protection by designing and manufacturing suitable enclosure solutions for mining sites to prevent expensive breakdowns, maintenance and injury.

In the residential field, B&R offers a range of product solutions to suit single dwellings, multi-tenancy buildings or commercial premises, with all products complying to Australian Supply Authority rules and regulations.

The range includes modular solutions for power distribution in commercial spaces such as shopping centres, large office complexes, and all manner of industrial, infrastructure and mining applications.

Meanwhile, B&R’s Data and ICT products range from server racks and cabinets to uninterruptible power supply to weatherproof 19-inch rack enclosures.

“B&R champions the virtues of quality, innovation, service and value”

Ben Bridges, Co-CEO, B&R Enclosures

PEOPLE AT THE CORE

At the backbone of this comprehensive offering, the company maintains what Bridges describes as, “an agile people-centric culture”.

“The workplace culture at B&R is characterised by a willingness to build the capabilities required to improve our manufacturing processes,” he continues.

“Our people management is really about providing roles and opportunities for individuals to get qualified and excited to do better, to experience challenges at work. Depending on the needs of the business or the market, we can move quickly, and our people move with us.”

As such, B&R employees are valued and cared for, with ample opportunity for professional development. This emphasis on empowerment is critical in ensuring a sense of security for staff, encouraging agility and guaranteeing that they are willing to thrive in alignment with the company as it continues to introduce the latest technologies.

B&R’s strengths in managing relationships with staff and clients, also translates to the way in which it handles the supply chain.

“B&R is an expert at supply chain management and often provides this service for customers,” states Bridges.

“Supplier and partner relationships are crucial to B&R as the organisation uses a variety of raw and finished goods in the manufacture of products from simple metal enclosures to integrated electrical solutions.”

These critical relationships have risen to the fore now more than ever, as global supply chain disruptions continue to threaten the reliable delivery of components manufactured overseas.

“As a manufacturer of enclosures and data racks from metal sheet, supply chain relationships, particularly local suppliers in Australia are crucial,” Bridges comments.

“We provide complete enclosure solutions for the protection of equipment and the safety of people who install and operate them”

Ben Bridges, Co-CEO, B&R Enclosures

THE JOURNEY TO DIGITALISATION

The topic of improving manufacturing processes extends both to people, and technology, fostering the symbiosis that can exist between the two to advance operations. This way, the workforce does not feel resistant, nor are their duties threatened by the latest investments.

As Ben Bridges attests, “when we do bring in extra equipment, like automated robotic equipment, the feeling is definitely more of excitement.” Indeed, it is a holistic approach that B&R adopts to capability building, furthering the capabilities of its people adjacent to manufacturing systems and processes.

Fuelling this investment is the creation of new products, the desire to explore new markets, and improving output and product quality.

B&R is currently making major strides on a journey towards Industry 4.0 which aims to digitise the business to enable integration with major project operators, improving efficiency and reducing costs and supply times across the entire project supply chain.

Through advanced manufacturing, B&R is actively moving from paper-based processes to technology-driven solutions to digitise many aspects of the business, from interactions with customers during the design process through to developing a supply plan and scheduling jobs on the shop floor.

The company is currently undertaking a major project to provide an end-to-end fully digitised workflow solution. Digital integration software is being incrementally implemented using agile project management methodology. The system uses 3-D technology to co-design custom solutions with clients, then create project templates, chart the manufacturing process, and schedule and assign tasks through to delivery date. It replaces many existing paper-based processes and represents a significant change in day-to-day operations.

“At B&R we’re using agile methods to drive continuous improvement through small but frequent changes, to transform without creating massive disruption.”

By implementing a more efficient workflow, B&R is providing faster and more comprehensive services to customers, whilst simultaneously improving jobs and the working environment for employees.

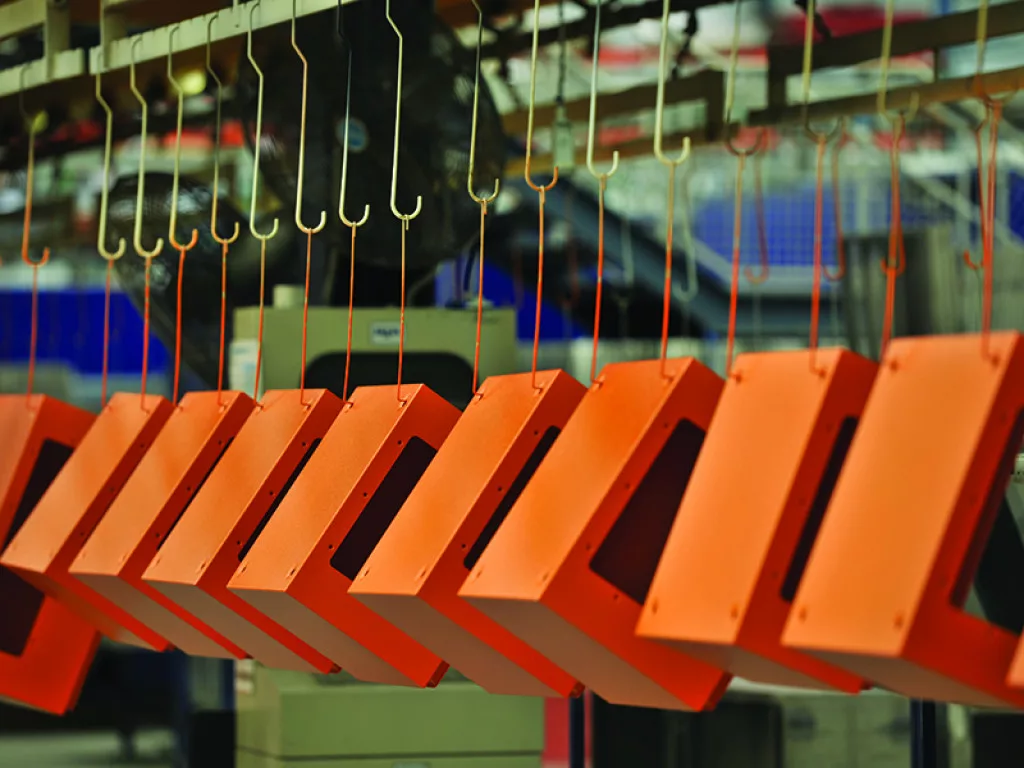

Recent strategic investments over the last few years include the purchase of a fully automated fibre laser welding machine, an automatic punching and bending machine, and a laser cutting machine. Investment in robotic machinery and new technologies is undertaken strategically to maintain and improve B&R’s proposition in the market.

“Electrical and component integration into our enclosures is an increasingly core part of the business. We used to manufacture the enclosure and give it to switchboard builders to do the electrical integration, and now we have started to bring that work in-house providing extra value to these end customers.”

A critical move in maintaining B&R’s competitive market edge, this investment in the latest technologies has been instrumental in the company’s recent success in winning a Queensland Government Cross River Rail project tender.

Looking ahead, B&R will continue to support the numerous infrastructure and major projects taking place across Australia and the wider APAC region. Continuing in the same vein as the company has done for the past 67 years, B&R will remain alert to identifying and leveraging new opportunities for growth across a range of markets.