Manufacturing for the healthcare sector across Asia, we speak to Oliver Healthcare Packaging about its innovative and tech-centred approach to answering the industry’s demand.

PROTECTING THE LIFE INSIDE

The healthcare industry has become the core focus of the globe for over a year now.

The COVID-19 pandemic threw into action a worldwide push to develop and manufacture vaccines on an international scale. And alongside vaccine development, a multitude of different yet related fields have been spurred forward to answer the varied demands of vaccine rollouts.

For Oliver Healthcare Packaging, the market is booming. The company specialises in manufacturing a variety of flexible packaging materials used in the medical device, biologics, diagnostics and pharmaceutical industries. These products are highly regulated within an industry of the same nature, and Oliver partners with customers by providing packaging design and technical expertise to ensure that they receive the best they can.

As a manufacturer in the healthcare industry, Oliver Healthcare Packaging has been subject to and fuelled by the incredible global efforts working against the pandemic.

MARKET GROWTH

“We currently have seven manufacturing sites and five technical development centres, with over 1,000 employees globally,” begins Dr. Aldin Velic, General Manager of Southeast Asia.

Velic and his team cover Australia, New Zealand and all of Asia excluding China; countries and markets that are incredibly diverse, with different stages of maturity, infrastructure and healthcare access.

“We are seeing some of the largest growth in healthcare spending coming from Southeast Asia,” Velic explains further. “The aging population, government spending and access to healthcare are driving double digit growth in these market segments. Regulatory standards are also increasing in these markets; that is encouraging for us, because we know that people are getting better care, while ensuring patient safety.”

EXPERIENCE IN THE FIELD

With over 15 years of experience spanning from supply chain operations, business development, mergers and acquisitions, and marketing; Velic entered the healthcare industry with a multi-disciplinary perspective to strategy planning and execution, having worked in public and private equity backed organisations.

“I’ve been fortunate to have spent a large portion of my initial career in roles that included a hybrid of operations and sales,” Velic tells us. “Understanding operational capabilities and constraints and linking these with customer needs gave me a strong understanding of how a constant balancing act is needed.

“Over the last 15 years, I have been in leadership roles within operations, sales, marketing and strategy. The first part of my career was primarily focused on supply chain services; in both heavy asset and capital-intensive industries as well as software-as-a-service organisations (private and public). I have always had an interest in healthcare, so when the opportunity presented itself to work with Oliver, it was an easy decision to make the leap.”

“Oliver’s history of innovation is what has enabled us to become an industry leader today.”

Oliver Healthcare

HEALTHCARE TECHNOLOGIES

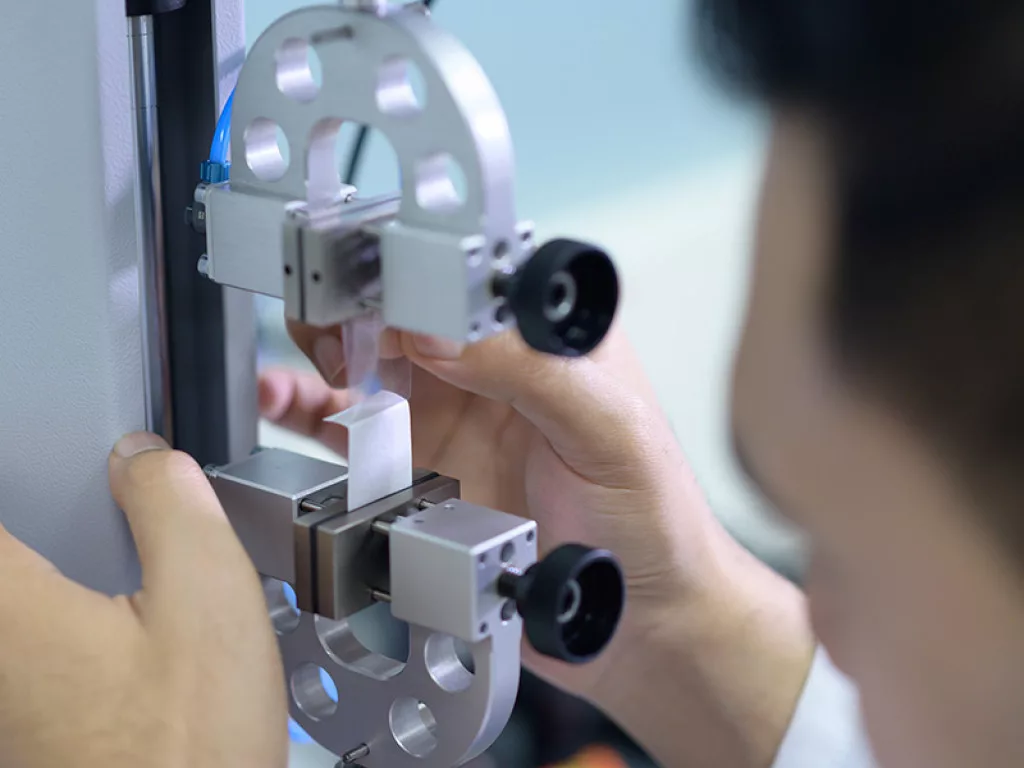

Oliver Healthcare Packaging makes use of the latest technology to aid it in its mission to provide world-class healthcare packaging solutions to customers worldwide. For example, these different technologies can be used to apply adhesives to film, paper or Tyvek® substrates, as Velic comments.

“Oliver has two technologies; one is a water-based coating technology and the second is a hot-melt coating technology,” he tells us.

“For applications where particulate and bioburden are of critical importance, we’ve found that our hot-melt (Xhale) coating technologies outperform competitors by a large degree.

“Oliver is the only company in the industry to offer hot-melt coatings and our customers place their trust in us when it comes to highly stringent requirements.”

All of Oliver’s manufacturing sites are 13485:2016 certified; the company follows Good Manufacturing Practices (GMP) and its technical teams advise and help set the standards for sterile barrier packaging testing requirements as mandated by the Federal Drug Administration (FDA). Oliver Healthcare Packaging are experts in this field, and the company’s sole focus is on the field of healthcare, whereas its competitors are primarily non-healthcare focused.

INNOVATION AND EVOLUTION

Despite the high-level of regulation within the healthcare industry, Velic assures us that there is still plenty of opportunity for innovation and the development of momentum in the sector.

“Oliver has evolved through acquisition, over the past 10 years,” he says. “Some of these include Tolas Healthcare which was founded in the 1980s and provided us with water-based coating technologies, along with Mangar Medical Packaging, one of the largest pouch convertors in the US (also founded in the 1980s), that added considerably to our product offering and size.”

Oliver Healthcare Packaging has continued to expand its product and service offerings in recent years.

“In 2019, we acquired a company called CleanCut Technologies, based in Anaheim, California,” Velic elaborates. “This expanded our product portfolio significantly to include high-density polyethylene cards primarily used to mount catheters, stents and minimally invasive products to a backer card. This product has won numerous innovation awards due to its recyclability and aseptic presentation in hospitals, not to mention the lower overall cost for companies.”

And in 2020, Oliver acquired Kansas City Designs, renaming it Oliver Design. This boutique design firm has added considerable depth and expertise in design capabilities, especially within the company’s pharmaceutical and biotechnology customer base.

“Our plan is to continue to grow our business organically, through strong service and quality commitments,” Velic informs us. “We are always open to non-organic opportunities that enhance our product offerings, geographic reach and service to our customers as well.”

“Our plan is to continue to grow our business organically, through strong service and quality commitments”

Dr. Aldin Velic, General Manager Southeast Asia, Oliver Healthcare PackagingRESPONSIBILITY BEYOND BUSINESS

Oliver Healthcare Packaging ensures that it is a company that operates with the environment and community (both global and local) in mind.

In the company’s recent sustainability report, Oliver highlighted its impact to the environment and its people.

“One challenge in recycling all elements of the sterile barrier is the inherent biocontamination that occurs in an operating room,” Velic elaborates. “As a result, we focus on operational efficiencies in how we manufacture these products for our customers as well as how they are utilised during transportation, distribution and storage.”

An example of this is the company’s cutting edge, award-winning Clipless Catheter Dispensers, which were recognised as the winner in the Packaging Design of the Year category at Healthcare Asia Medtech Awards 2021, and that can reduce the company’s packaging footprint by 20-30 percent on average. This saves both warehouse and transportation costs, while also reducing the number of packages used throughout the process of delivering a device from manufacturing to the operating room. Two of Oliver’s largest manufacturing sites, representing approximately 56 percent of the company’s global sales volume production, sends zero waste to landfills.

“Our technical development centres focus on evaluating the shape, size and functionality of each piece of packaging,” Velic says. “From there, our design and packaging engineers create designs that offer the most innovative and sustainable solutions while addressing various sterilisation modality requirements and integrating costs, waste and recyclability requirements.

“The early involvement in the development of a new device has helped shave significant manufacturing and raw material cost from our customer’s total landed cost; while also addressing the impact to environment, people and economic wellbeing.”

HEALTHCARE MOVING FORWARD

For the foreseeable future, Oliver Healthcare Packaging’s key priorities revolve around ensuring customer success by providing an ample supply in a market with high-demand variability, especially during a pandemic which has caused many disruptions to the healthcare value chain.

“We are fortunate to have an ownership structure where long-term investment and business results are the norm,” Velic tells us. “This management philosophy results in appropriately carrying inventory and investing in capacity ahead of increasing demand from our customers.

“Providing sustainable lead times to our customers, while adhering to growing regulatory requirements are challenging, but also key priorities for us in this industry.”